Are you tired of your old, worn-out flooring and looking for a modern, durable alternative? Do you find yourself overwhelmed by the plethora of options available in the market? You’re not alone. Finding the perfect aesthetically pleasing and functional flooring can be daunting.

Look no further. PVC flooring is the ultimate solution for your flooring needs in 2023. Known for its durability, ease of installation, and wide range of design options, PVC flooring is rapidly becoming the go-to choice for homeowners and businesses.

So, why should you keep reading? By the end of this guide, you’ll be equipped with all the knowledge you need to install PVC flooring like a pro. Let’s dive in.

What is PVC Flooring?

PVC flooring, or Polyvinyl Chloride flooring, is a synthetic flooring solution that has gained immense popularity over the years. I’ve been in the flooring industry for quite some time, and I can confidently say that PVC flooring is a game-changer. Made from natural and synthetic polymer materials, it produces a highly durable and versatile flooring option. The manufacturing process involves layering a PVC core with a vinyl top layer and a protective coating. This ensures the flooring is robust and resistant to scratches, dents, and stains.

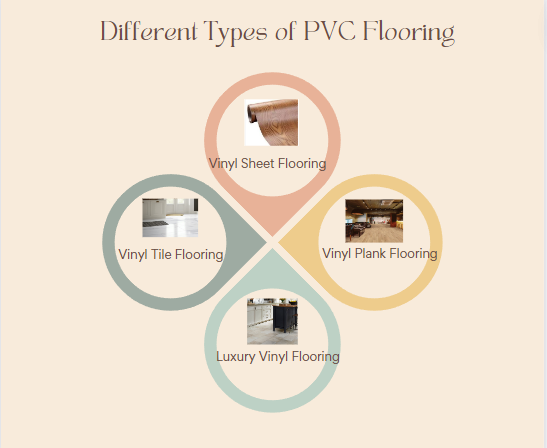

Types of PVC Flooring Available

Regarding PVC flooring, you’re not limited to just one type. Over the years, I’ve had the opportunity to install various kinds of PVC flooring, and here are some of the most common ones:

- Sheet PVC Flooring: Comes in large, flexible sheets and is best suited for commercial spaces.

- TilePVC Flooring: These are individual squares that mimic the look of ceramic tiles but offer the durability of PVC.

- Plank PVC Flooring: These planks are designed to resemble hardwood and provide a more natural look.

- Interlocking PVCTiles: These are easy-to-install tiles that lock together, providing a seamless look.

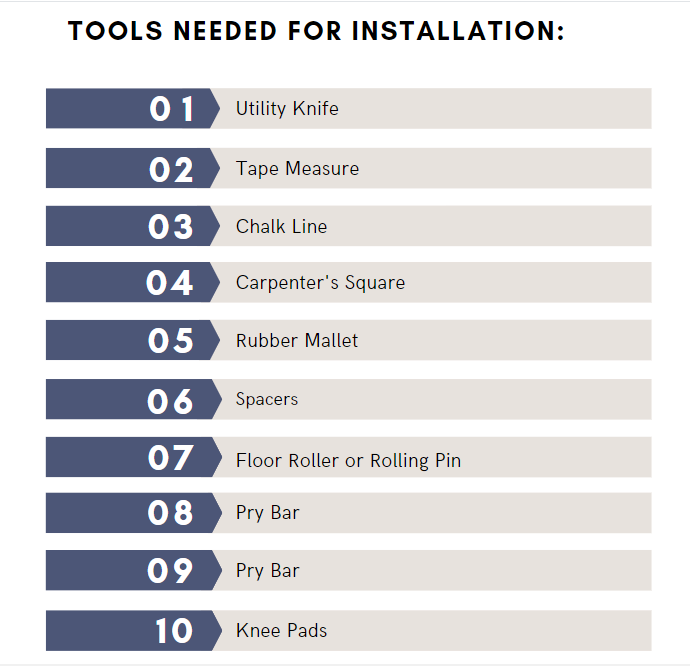

Tools Needed for Installation

Before you dive into the installation process, it’s crucial to have all the necessary tools on hand. Trust me, and nothing derails a project faster than realizing you’re missing a key tool halfway through. Based on my extensive experience of installing PVC flooring, here’s a comprehensive list of tools you’ll need:

Utility Knife

For cutting PVC sheets or tiles. This is your go-to tool for making precise cuts on your PVC flooring.

Tape Measure

To accurately measure the area where the flooring will be installed. Essential for calculating the area of the room, helping you purchase the right amount of flooring.

Chalk Line

For marking straight lines on the subfloor. This tool helps you mark where your first row of flooring will go, ensuring a straight installation.

Carpenter’s Square

To ensure your cuts are perfectly square. Use this to ensure your cuts are at perfect right angles, which is crucial for a seamless fit.

Rubber Mallet

To help lock the flooring pieces into place. This helps in locking the flooring pieces together without damaging them.

Spacers

To maintain a consistent gap between the flooring and the wall. These are placed between the wall and the flooring to allow for expansion and contraction.

Floor Roller or Rolling Pin

To press down the flooring, ensuring it sticks well to the adhesive. Rolling ensures that the flooring bonds securely to the adhesive on the subfloor.

Pry Bar

For removing old flooring or baseboards. Useful for removing any existing flooring or obstacles.

Adhesive Trowel

If you’re using adhesive, this tool helps spread it evenly. This tool enables you to spread adhesive evenly, ensuring a secure bond between the flooring and the subfloor.

Knee Pads

For your comfort during installation. Installing flooring can be hard on your knees, so knee pads provide much-needed comfort.

Preparing Your Space

Steps to Clean and Prepare the Surface

The surface underneath needs to be immaculate before you even think about laying down your new PVC flooring. I’ve seen too many projects go awry because of inadequate surface preparation. Here’s how to get it right:

- Remove Old Flooring: If you have existing flooring, it must be removed. Use a pry bar for this task.

- Clean the Subfloor: Vacuum to remove dust, dirt, or debris.

- Check for Moisture: Use a moisture meter to ensure the subfloor is dry. Any moisture can compromise the adhesive.

- Apply Primer: Some types of PVC flooring require a primer to be applied to the subfloor. Follow the manufacturer’s instructions if this is the case.

How to Measure Accurately

Accurate measurements are crucial for a successful installation. Here’s how to get it right:

- Measure the Room: Use a tape measure to get the length and width of the room. Multiply these to get the total square footage.

- Add Extra: Always buy 10% more flooring than your measurements to account for cuts and errors.

- Mark Starting Point: Use a chalk line to mark where your first row will go, ensuring it’s straight.

Suggestions for Dealing with Uneven Surfaces

Uneven surfaces can be a real headache when installing flooring. Here are some suggestions to tackle this issue:

- Use a Level: Check the evenness of the subfloor. If it’s uneven, you’ll need to address this first.

- Self-Leveling Compound: A self-leveling compound can create a smooth surface for minor unevenness.

- Plywood: For more significant issues, laying down a plywood subfloor can provide a level surface for your PVC flooring.

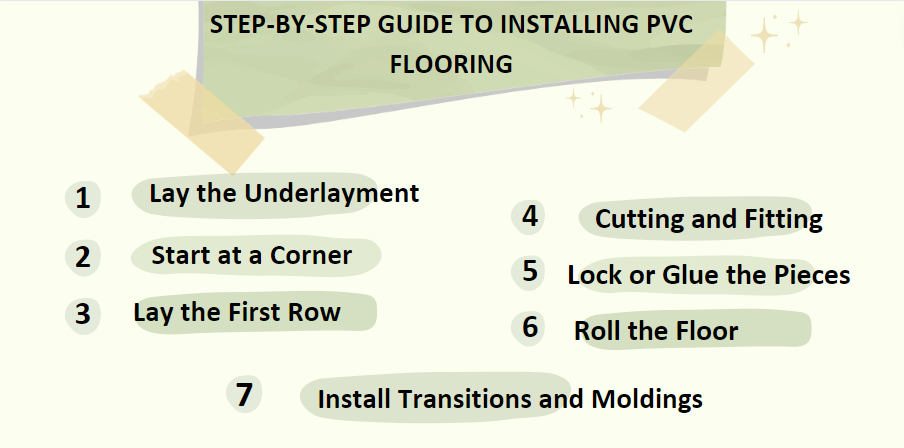

Step-by-step Guide to Installing PVC Flooring

Now that you’ve prepared your space, it’s time to get to the installation. Having installed countless PVC floors, I can guide you through the process to ensure a smooth and successful project. Here’s how to go about it:

Step 1: Lay the Underlayment

The underlayment serves as a cushion between the subfloor and your new PVC flooring. Roll out the underlayment material across the entire subfloor, ensuring it lies flat without any wrinkles or bubbles. Cut the edges to fit the room’s dimensions. If your underlayment comes in rolls, overlap the seams by about an inch and use tape to secure them. This ensures a smooth and even surface for your PVC flooring.

Step 2: Start at a Corner

Starting at a corner ensures you have a straight edge to guide the rest of the installation. Align the first piece of your PVC flooring in the corner, ensuring it’s flush against both walls. This is your starting point, and aligning this piece perfectly is crucial as it sets the tone for the entire installation.

Step 3: Lay the First Row

Using the chalk line you’ve previously set as a guide, begin laying down the first row of PVC flooring. Make sure each piece locks in securely with the previous one. If your flooring type requires adhesive, apply it to the subfloor and not the PVC pieces. The first row is critical because it guides all subsequent rows, so take your time to ensure it’s perfectly straight.

Step 4: Cutting and Fitting

As you move along, you’ll encounter obstacles like door frames, vents, or corners that require cutting the PVC flooring. Use a utility knife for precise cuts, and always double-check your measurements before cutting. A carpenter’s square can be invaluable here for ensuring your cuts are at the right angles.

Step 5: Lock or Glue the Pieces

Depending on the type of PVC flooring you’ve chosen, you’ll either lock the pieces together or glue them down. If they close together, use a rubber mallet to gently tap the pieces into place, ensuring a snug fit. If you’re using adhesive, use a trowel to spread it evenly on the subfloor before laying each piece.

Step 6: Roll the Floor

Once all the pieces are laid down, it’s time to secure them. Use a floor roller or a rolling pin to cover the entire floor. This ensures that the flooring bonds well with the adhesive and that interlocking pieces are securely locked.

Step 7: Install Transitions and Moldings

The final step involves installing transition strips at doorways and moldings around the room’s edges. This gives your flooring project a finished, professional look. Measure and cut each piece of molding or transition strip to fit, and secure them in place using either nails or adhesive, as appropriate for your specific product.

Tips and Tricks for Each Step

- Underlayment: Make sure there are no wrinkles in the underlayment for a smooth surface.

- First Row: The first row sets the tone for the entire installation, so double-check to ensure it’s straight.

- Cutting: Always use a sharp utility knife for clean cuts.

- Adhesive: If using adhesive, spread it evenly with a trowel for a secure bond.

- Rolling: Apply even pressure when rolling to ensure the flooring bonds well to the subfloor.

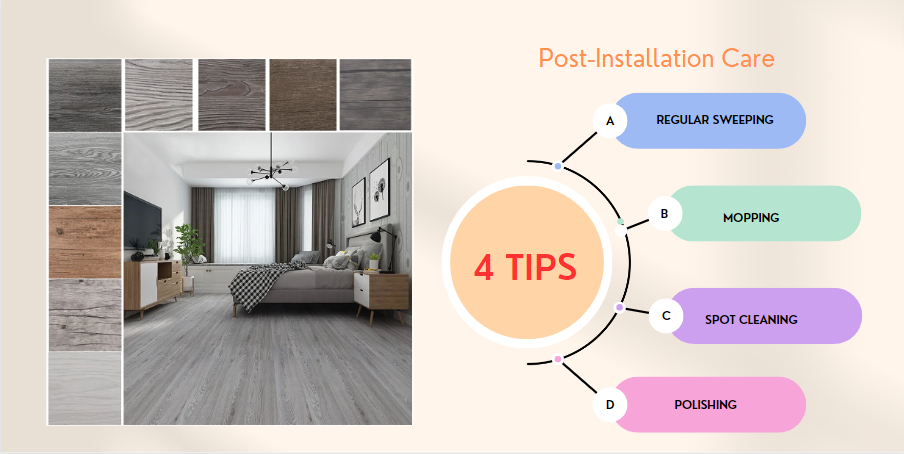

Post-Installation Care

Congratulations on your new PVC flooring! Now, the key to its longevity is proper care and maintenance. Based on my years of experience in the flooring industry, here’s how to keep your floor looking new:

- Regular Sweeping: Use a soft-bristle broom to sweep away dirt and debris. This prevents scratches and maintains the floor’s shine.

- Mopping: Use a damp mop with a mild cleaner to clean the floor. Avoid using excessive water, as it can seep into the edges.

- Spot Cleaning: A soft cloth with mild detergent works well for spills or stains. Always clean spills immediately to prevent staining.

- Polishing: Every few months, consider using a PVC floor polish to restore the floor’s shine. Make sure to follow the manufacturer’s guidelines.

How to Handle Potential Problems

- Gaps: If you notice gaps between the flooring pieces, you can usually tap them into place with a rubber mallet.

- Bubbles or Wrinkles: These are often due to an uneven subfloor or poor adhesive application. You may need to lift the affected area and reapply the adhesive.

- Damaged Pieces: Always inspect each piece before installation. If you find a damaged piece, replace it immediately.

Conclusion

Installing PVC flooring is easier than you might think. We’ve gone through all the steps, from getting your room ready to laying down the flooring and taking care of it afterward. Each part has simple guidelines to follow. If you stick to them, you’ll end up with a great-looking floor that will last a long time. The tips in this guide are based on real experience, so you can trust they’ll work for you.

So, why not give it a try? You’ll not only save money by doing it yourself, but you’ll also feel proud of what you’ve accomplished. And if you ever get stuck, just come back to this guide. It’s like having a helpful friend by your side, making sure everything goes smoothly.