Are you struggling with uneven, unattractive floors that ruin the aesthetic of your home? Is the thought of a complicated installation process holding you back from upgrading to PVC flooring? You’re not alone. Many homeowners hesitate to take the plunge due to these concerns.

Look no further; gluing PVC flooring is easier than you think. With the right tools and a step-by-step guide, you can achieve a seamless, beautiful floor that enhances the look of your space and offers durability and ease of maintenance. So why wait? Dive into this comprehensive guide for 2023 and transform your floors today!

What is PVC Flooring?

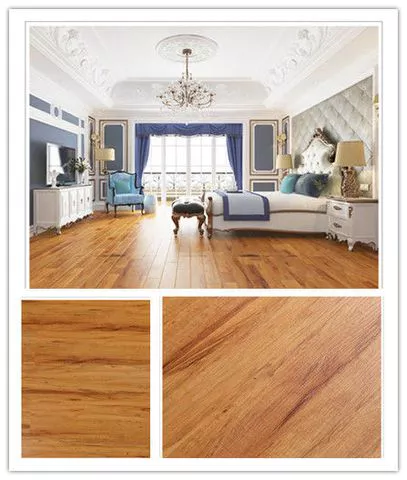

PVC flooring, or Polyvinyl Chloride flooring, is a synthetic flooring solution that has gained immense popularity in recent years. Made from natural and synthetic materials, PVC flooring offers a cost-effective and versatile option for indoor spaces. I’ve overseen numerous installations and can attest to its adaptability and ease of use. It’s a go-to choice for residential and commercial settings, from kitchens and bathrooms to offices and retail spaces.

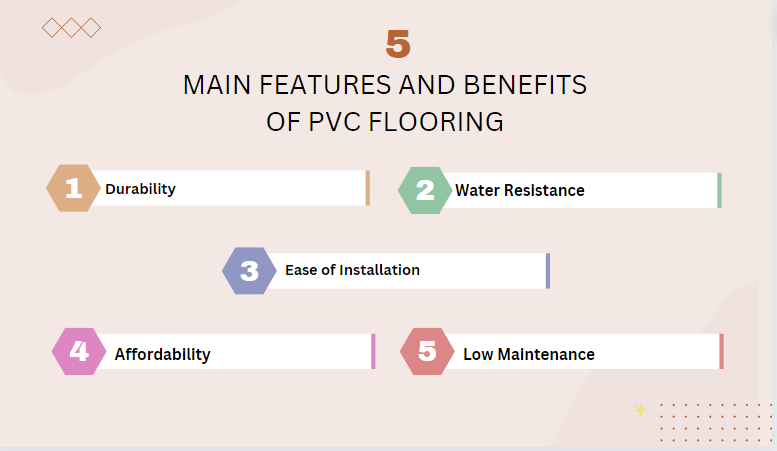

Main Features and Benefits of PVC Flooring

- Durability: One of the standout features of PVC flooring is its durability. It can withstand heavy foot traffic, making it ideal for busy households and commercial spaces. Its resilience is one of the reasons why flooring experts, including myself, recommend it.

- Water Resistance: PVC flooring is inherently water-resistant, which makes it an excellent choice for areas prone to moisture, like bathrooms and kitchens. You can trust this material to hold up well against spills and leaks.

- Ease of Installation: As someone in the flooring industry for years, I can vouch for the simplicity of installing PVC flooring. It’s a project that even DIY enthusiasts can undertake with the right guidance.

- Affordability: Compared to other flooring options like hardwood or tile, PVC flooring is relatively inexpensive. Yet, it offers a high-quality look that can elevate the aesthetics of any space.

- Low Maintenance: Once installed, PVC flooring is easy to maintain. A simple sweep and mop are generally all props needed to keep it looking new, making it a practical choice for those who don’t have the time for extensive upkeep.

Necessary Tools and Materials for Installing PVC Flooring

Before you embark on your PVC flooring installation journey, gathering all the necessary tools and materials is crucial. Here’s a comprehensive list to get you started:

- Measuring Tape

Accurate measurements are the foundation of any successful flooring project. I’ve found that a good-quality measuring tape can make a difference.

- Utility Knife

This is used for cutting PVC flooring sheets or tiles. A sharp utility knife ensures clean, precise cuts.

- Straight Edge or Ruler

A straight edge helps guide your utility knife for those perfect cuts. Trust me, it’s a lifesaver for maintaining straight lines.

- Adhesive (Flooring Glue)

The adhesive is what bonds the PVC flooring to the subfloor. Make sure to choose a high-quality adhesive designed for PVC flooring for best results.

- Notched Trowel

This tool helps spread the adhesive evenly. It’s essential for a secure bond between the flooring and the subfloor.

- Rubber Mallet

A rubber malletgently tapsp the PVC flooring into place, ensuring a snug fit.

- Spacers

These are used to maintain an even gap around the edges of the room, allowing for expansion and contraction.

- Chalk Line

A chalk line will help you mark your starting point and keep your installation aligned.

- Pencil

For marking measurements and cut lines directly on the PVC flooring.

- Safety Gear (Gloves, Goggles)

Safety should always be a priority. Gloves protect your hands during cutting, and goggles keep your eyes safe from flying debris.

Preparations Before Gluing PVC Flooring

Before you even think about gluing down your PVC flooring, it’s crucial to prepare the floor surface adequately. A well-prepared surface ensures the adhesive bonds correctly, leading to a more durable and long-lasting installation. Too many projects go awry due to inadequate preparation, so don’t skip this step.

Instructions on How to Clean and Level the Floor Surface

- Cleaning: Start by sweeping and vacuuming the floor to remove dust, dirt, and debris. If you’re working on a particularly dirty or stained surface, consider using a malign your installation roughly.

- Leveling: Check the floor for any uneven spots. If you find any, you’ll need to use a self-leveling compound to even it out. Follow the manufacturer’s instructions for the best results. I’ve found that a level floor significantly improves the final look and durability of PVC flooring.

Steps on Marking the Floor Layout

- Find the Center: Use your measuring tape and chalk line to find the center of the room. Mark this point clearly, as it will serve as your starting point.

- Draw Guidelines: From the center, draw straight lines towards each wall using your chalk line. These lines will guide your PVC flooring installation, ensuring it’s aligned correctly.

- Check for Square: Use the 3-4-5 triangle method to check if your lines are square. Adjust as necessary before proceeding with the installation.

Step-by-Step Guide to Gluing PVC Flooring

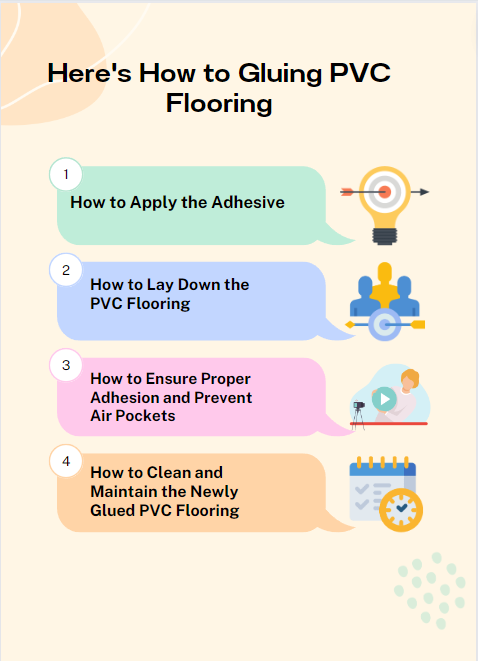

How to Apply the Adhesive

- Mix the Adhesive: Stir the adhesive well before use. Make sure it’s at room temperature for optimal performance.

- Apply the Adhesive: Using a notched trowel, spread a thin adhesive layer onto the subfloor. Work in small sections to prevent the glue from drying out.

- Let it Tack: Wait for a few minutes until the adhesive becomes tacky to the touch. This is crucial for a strong bond.

How to Lay Down the PVC Flooring

- Start at the Center: Begin laying your PVC flooring at the center point you marked earlier.

- Align and Press: Align the flooring with your chalk lines and press it firmly into the adhesive.

- Tap Gently: Use a rubber mallet to tap the flooring, ensuring it’s fully embedded in the adhesive.

Steps on How to Ensure Proper Adhesion and Prevent Air Pockets

- Roll the Floor: Use a floor roller to review the newly laid PVC flooring. This ensures proper adhesion and eliminates any air pockets.

- Check for Bubbles: Walk around and inspect the floor for any raised areas or bubbles. If you find any, use your mallet to tap them down.

How to Clean and Maintain the Newly Glued PVC Flooring

- Initial Cleaning: Wait at least 24 hours for the adhesive to be cured before cleaning the floor. Use a damp mop and mild detergent for the first cleaning.

- Ongoing Maintenance: For daily upkeep, a simple sweep and mop will suffice. For deeper cleaning, you can use specialized PVC floor cleaners.

Common Mistakes to Avoid When Gluing PVC Flooring

List of Common Pitfalls During the PVC Flooring Installation Process

- Skipping Surface Preparation: Many people underestimate the importance of a clean, level surface and jump straight into gluing the PVC flooring.

- Using the Wrong Adhesive: Not all adhesives are suitable for PVC flooring. Using the wrong type can lead to poor adhesion and a host of other issues.

- Ignoring Manufacturer’s Instructions: Each brand of PVC flooring may have specific requirements for installation. Ignoring these can result in a flawed finish.

- Rushing the Process: Patience is key. Rushing through the steps can lead to mistakes that are hard to correct later.

- Neglecting Safety Measures: Failing to use safety gear can result in injuries. Always prioritize safety.

Tips on How to Avoid These Mistakes

- Invest Time in Preparation: As someone who has seen the consequences of poor preparation, I can’t stress this enough. Take the time to clean and level your surface.

- Choose the Right Adhesive: Make sure to use an adhesive that is specifically designed for PVC flooring. If you’re unsure, consult with professionals or trusted sources.

- Follow Manufacturer’s Guidelines: Always read and follow the manufacturer’s instructions. They are provided to ensure the best possible outcome.

- Be Patient: Good things take time, and this is especially true for flooring installation. Take your time to ensure each step is done correctly.

- Prioritize Safety: Always use the recommended safety gear, including gloves and goggles, to protect yourself during the installation process.

Advantages of Having a Professionally Glued PVC Floor

Benefits and Durability of Properly Installed PVC Flooring

When PVC flooring is installed correctly, especially when glued down with precision, the benefits are manifold. First and foremost, you’re looking at a floor that can last for years without showing signs of wear and tear. Its durability is something I’ve witnessed firsthand in numerous installations. Properly glued PVC flooring is resistant to water damage, scratches, and dents, making it an ideal choice for high-traffic areas in both residential and commercial settings.

Potential Cost Savings from Doing the Installation Correctly

Another significant advantage of a professionally glued PVC floor is the potential for cost savings in the long run. A poorly installed floor will require frequent repairs and may even need to be replaced entirely, leading to additional expenses. On the other hand, a well-installed PVC floor minimizes these risks, saving you both time and money. I’ve consulted on projects where the initial investment in professional installation paid off multiple times over in the form of reduced maintenance and repair costs.

Conclusion

In this comprehensive guide, we’ve covered everything from the basics of what PVC flooring is to the intricate details of gluing it down professionally. With the right tools, preparation, and attention to detail, you can achieve a durable and aesthetically pleasing floor that offers both functionality and cost savings. Having been involved in numerous successful installations, I can assure you that the effort you put into this project will pay off in the long run. So go ahead, take the plunge and transform your floors today—you won’t regret it!