Looking to upgrade your home flooring with something that’s both durable and water-resistant? SPC click lock flooring is the answer! And the best part? It’s easy to install by yourself with our step-by-step guide. Whether you’re a seasoned DIYer or just starting out, we’ve got you covered with all the tips and tricks you need for a successful installation. So, let’s dive in and transform your home with beautiful and practical SPC click lock flooring.

step-by-step Installation Instructions

Laying Underlayment

Installing the First Row of Planks

Clicking in Subsequent Rows

Cutting and Fitting Planks

Finishing Touches

Do you want to learn more about the instructions for installing SPC Click Lock Flooring? Read on for our step by step guide !

Definition of SPC Click Lock Flooring

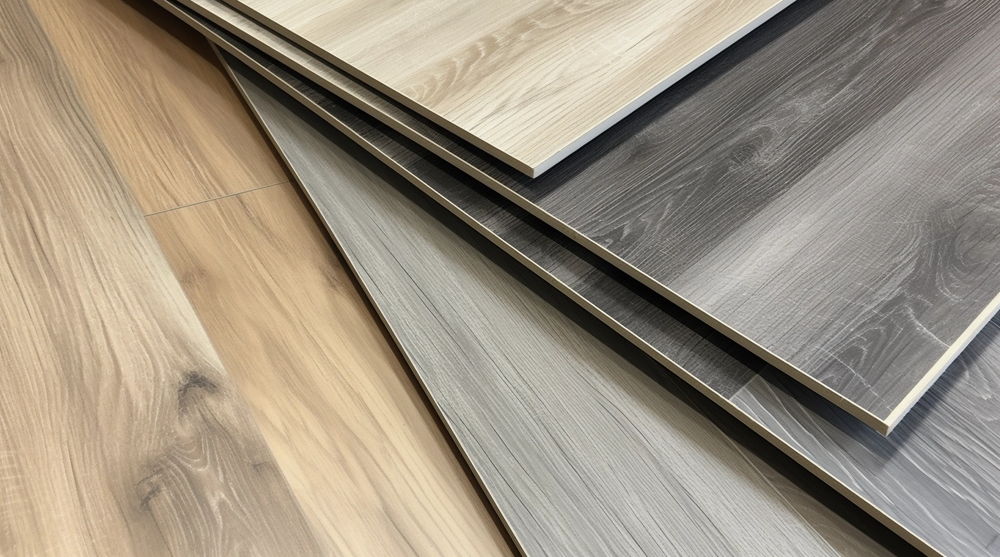

SPC click lock flooring is a type of rigid core vinyl flooring, which consists of a combination of stone and plastic composites. The result is an incredibly durable and water-resistant material that’s perfect for high-traffic areas, such as kitchens, bathrooms, and entryways. The “click-lock” installation system means that the planks snap together easily without any need for adhesives or nails, making it an ideal choice for DIYers who want to save on installation costs.

Importance of an Installation Guide for Homeowners

Installing flooring can be a daunting task for homeowners, especially if they’ve never done it before. That’s why an installation guide for SPC click lock flooring is essential. Not only does it provide step-by-step instructions for the installation process, but it also covers tips and tricks for preparing the subfloor, acclimating the flooring, and troubleshooting common issues. With a thorough installation guide, homeowners can feel confident in their ability to install SPC click lock flooring themselves, saving money on labor costs while achieving professional-looking results.

Advantages of Using SPC Click Lock Flooring

- Durability and Resilience

One of the key advantages of SPC click lock flooring is its durability and resilience. Due to its rigid construction and strong interlocking system, it is highly resistant to damage from heavy foot traffic, scratches, and dents. This makes it an ideal choice for both residential and commercial spaces where a durable and long-lasting flooring solution is needed.

- Waterproof and Moisture-resistant

Another advantage of SPC click lock flooring is its waterproof and moisture-resistant properties. Unlike other types of flooring such as hardwood or carpet, SPC click lock flooring can withstand exposure to water and moisture without warping or buckling. This makes it a great choice for high-moisture areas such as bathrooms, laundry rooms, and basements, as well as for homes with pets or young children.

- Easy to Clean and Maintain

SPC click lock flooring is also easy to clean and maintain. Its smooth surface makes it easy to wipe up spills and dirt, and its non-porous surface prevents stains and odors from penetrating. Additionally, it doesn’t require any special cleaning products or techniques, making it a low-maintenance flooring solution that can save homeowners time and money in the long run.

- Aesthetically Pleasing

SPC click lock flooring is aesthetically pleasing and can mimic the look of more expensive flooring materials like hardwood, ceramic tile, or stone. It comes in a wide variety of colors and patterns, allowing homeowners to choose a style that matches their décor preferences without breaking the bank. Additionally, the click-lock system ensures a seamless installation that looks professional and polished. Overall, SPC click lock flooring offers numerous advantages that make it a popular choice among homeowners and business owners alike.

Tools and Materials Needed for SPC Click Lock Flooring Installation

- Underlayment

Underlayment is an essential material that is used to provide a smooth and stable surface for the SPC click lock flooring. It helps to reduce noise, increase insulation and protect against moisture. Different types of underlayment are available, such as foam, cork or rubber, so it’s important to choose the right one based on the specific needs of your project.

- Cutting Tools

Cutting tools are necessary for trimming the SPC click lock flooring to fit around doorways, corners and other obstacles. Some examples of cutting tools include a circular saw, jigsaw or handsaw. When using cutting tools, it’s important to follow safety guidelines and wear protective gear such as goggles and gloves.

- Measuring Tape

Measuring tape is necessary to accurately measure the dimensions of the room and determine how much SPC click lock flooring is needed. Measuring tape can also be useful during the installation process to ensure that the planks are being cut to the appropriate size.

- Spacers

Spacers are small plastic pieces that are used to maintain a consistent gap between the SPC click lock planks and the walls. This gap allows for expansion and contraction of the flooring due to changes in temperature or humidity. Spacers are crucial for creating a professional-looking finish to the installation, as they help to ensure that the planks are aligned properly.

- Rubber Mallet

A rubber mallet is necessary for tapping the SPC click lock planks into place during installation without damaging them. This tool helps to force the planks together and create a tight fit between each piece. However, it’s important to use the mallet gently to avoid causing any damage to the planks or the subfloor.

Pre-Installation Preparation

- Floor Inspection and Cleaning

Before installing SPC click lock flooring, it’s important to inspect and clean the existing floor thoroughly. This includes removing any debris, dust or dirt that may be present on the surface. In addition, the subfloor should be inspected for any signs of damage or moisture issues that could affect the installation process. Any issues should be addressed prior to the installation to ensure a smooth and successful outcome.

- Acclimation of Flooring

Acclimation of the SPC click lock flooring is another crucial step in the pre-installation preparation process. This involves allowing the flooring to sit in the room where it will be installed for a period of time to adjust to the temperature and humidity conditions. This helps to prevent expansion or contraction of the planks after installation, ensuring a stable and long-lasting flooring solution.

- Layout Planning and Calculations

Layout planning and calculations are also important steps to take before beginning the installation process. This involves determining the starting point for the installation, deciding on the orientation of the planks, and calculating the amount of flooring needed to cover the entire space. Proper layout planning helps to ensure that the installation proceeds smoothly and efficiently, with minimal waste or mistakes along the way.

Step-by-step Installation Instructions

1.Laying Underlayment

Laying underlayment is the first step in the installation process of SPC click lock flooring. The underlayment should be placed perpendicular to the direction of the planks, and secured with tape or adhesive. This helps to create a smooth and stable surface for the planks to rest on.

2.Installing the First Row of Planks

Installing the first row of planks requires careful planning and measuring to ensure that it is straight and level. Spacers should be used to maintain a consistent gap between the planks and the wall, and the tongue should face away from the starting wall. The first row can be secured using adhesive or by clicking the planks together, depending on the manufacturer’s instructions.

3.Clicking in Subsequent Rows

Clicking in subsequent rows involves interlocking the planks using the “click-lock” system. Care should be taken to ensure that each plank is properly aligned and clicked into place before moving on to the next one. A rubber mallet can be used to gently tap the planks into place, if needed.

4.Cutting and Fitting Planks

Cutting and fitting planks is necessary when reaching the end of a row or around obstacles such as doorways or cabinets. Planks can be cut to size using a saw or other cutting tool, and spacers should be used to maintain a consistent gap between the planks and the wall. The final row may need to be trimmed to fit properly.

5.Finishing Touches

Finishing touches include installing any trim or molding around the perimeter of the room, and filling any gaps or seams with a seam sealer or caulking. The floor should be thoroughly cleaned and inspected for any loose or damaged planks, and furniture can be moved back into place.

Troubleshooting Tips

- Dealing with Uneven Subfloors

Uneven subfloors can be a major issue when installing SPC click lock flooring. To address this problem, homeowners should use a self-leveling compound or shim to even out the surface before installing the underlayment. Failing to address unevenness in the subfloor can result in gaps between the planks and a less-than-professional finish.

- Addressing Gaps and Buckling

Gaps and buckling can occur in SPC click lock flooring if the installation is not done properly or if the planks are not acclimated correctly. To address gaps, homeowners can use a seam sealer or caulking to fill in the spaces between the planks. Buckling can be addressed by removing the affected planks and reinstalling them, making sure that they are properly aligned and clicked into place.

- Correcting Misaligned Planks

Misaligned planks can be corrected by carefully disassembling the affected area and re-installing the planks in the correct position. This may involve trimming the planks to ensure a proper fit, or using spacers to maintain consistent spacing between the planks. A rubber mallet can be used to gently tap the planks into place, being careful not to damage the edges or corners of the planks.

Maintenance and Care for SPC Click Lock Flooring

- Regular Cleaning

Regular cleaning is essential for maintaining the appearance of SPC click lock flooring. Dust and debris should be swept or vacuumed regularly, and spills should be wiped up immediately to prevent staining or damage. A damp mop can be used for more thorough cleaning, but homeowners should avoid using abrasive cleaners or harsh chemicals that could damage the surface.

- Preventative Measures

Preventative measures can help to prolong the life of SPC click lock flooring. This includes using furniture pads to protect against scratches, placing mats or rugs at entryways to prevent dirt and debris from being tracked in, and avoiding exposure to direct sunlight or extreme temperature changes. Additionally, maintaining optimal humidity levels in the home can help to prevent the planks from expanding or contracting.

- Repairing Damaged Planks

Repairing damaged planks may be necessary over time due to normal wear and tear or accidental damage. To repair a damaged plank, homeowners should remove the affected plank and replace it with a new one. The replacement plank should be acclimated prior to installation, and care should be taken to match the color and pattern of the existing planks as closely as possible.

In conclusion, SPC click lock flooring is a versatile and cost-effective flooring solution that offers numerous advantages for homeowners. Its durability, water-resistance, ease of installation, and aesthetic appeal make it a popular choice for high-traffic areas and spaces with high moisture content. Proper pre-installation preparation, step-by-step installation instructions, and troubleshooting tips can help homeowners achieve professional-looking results when installing SPC click lock flooring themselves. Additionally, regular maintenance and care are essential for preserving the beauty and functionality of the flooring over time. By following these guidelines, homeowners can enjoy the benefits of SPC click lock flooring for years to come.