Looking for a comprehensive guide to SPC flooring acceptance standards and guidelines? Look no further than our expertly-crafted resource, which covers everything you need to know about this innovative flooring material. From tips on installation and maintenance to key performance indicators and product specifications, our guide is your go-to source for all things SPC flooring.

Subfloor preparation, acclimation, adhesive selection, and expansion gaps for installation. Wear layer thickness, slip, and impact resistance, and stability for performance indicators. Plank/tile dimensions, color and pattern variation, and VOC emissions for product specifications.

Know about the SPC floor acceptance standard specification and its purpose including the testing and inspection, installation, and maintenance requirements. Learn more about its criteria and procedures.

1. SPC floor acceptance standard specification

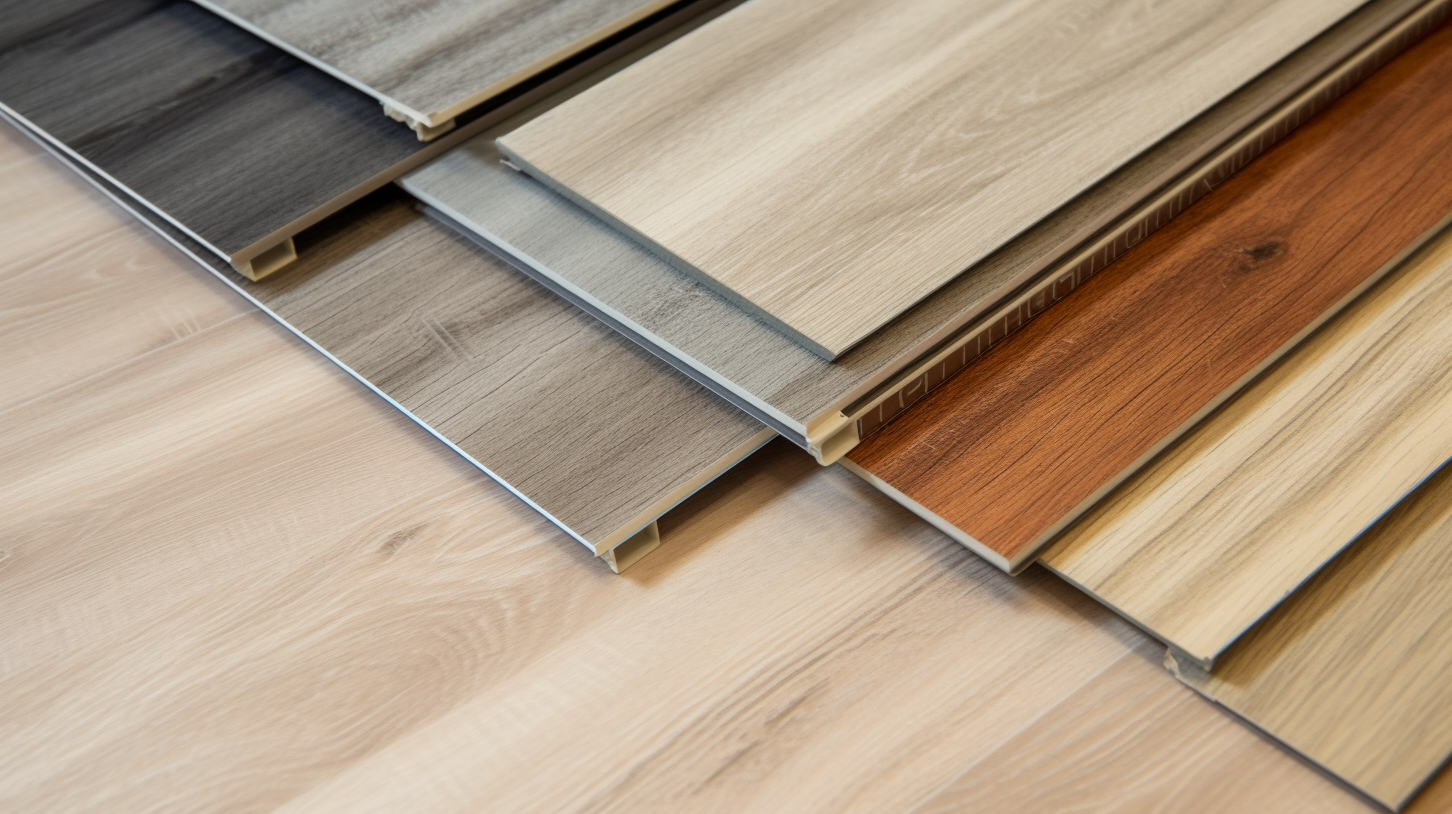

SPC (Stone Plastic Composite) flooring is a type of rigid core vinyl flooring that is becoming increasingly popular due to its durability, waterproofing, and ease of installation. To ensure that SPC flooring meets quality and performance expectations, there are specific acceptance standards and specifications to consider.

- Wear layer thickness: The wear layer is the topmost layer of SPC flooring that is responsible for protecting the surface from scratches, stains, and wear. The wear layer thickness should be at least 20 mils (0.02 inches) to ensure durability and longevity.

- Density: SPC flooring should have a high density to ensure its strength and stability. The density should be at least 1.4 g/cm³ (grams per cubic centimeter).

- Thickness: The thickness of SPC flooring should be at least 4 mm (0.16 inches) to ensure adequate support and durability.

- Slip resistance: SPC flooring should have a slip resistance rating of at least 0.5 to reduce the risk of slips and falls. The slip resistance can be measured using the coefficient of friction (COF).

- Formaldehyde emissions: SPC flooring should have low levels of formaldehyde emissions to ensure good indoor air quality. The formaldehyde emission levels should be less than 0.5 parts per million (ppm).

- VOC emissions: SPC flooring should have low levels of volatile organic compounds (VOC) emissions to ensure good indoor air quality. The VOC emissions levels should be less than 0.5 milligrams per cubic meter (mg/m³).

- Fire resistance: SPC flooring should have a fire-resistance rating of at least Class B1, which means that it is difficult to ignite and has low smoke production.

- Color and pattern variation: SPC flooring should have minimal color and pattern variation to ensure a uniform appearance.

- Stain resistance: SPC flooring should be resistant to stains caused by common household items such as coffee, wine, and oil.

- Impact resistance: SPC flooring should be able to withstand impact without cracking or denting.

By considering these accepted standards and specifications, you can ensure that the SPC flooring you choose will meet your expectations in terms of quality, durability, and performance.

2. Purpose of SPC floor acceptance standard specification

The purpose of SPC (Stone Plastic Composite) floor acceptance standard specification is to ensure that the SPC flooring products meet certain quality and performance standards. These standards are established to protect the end-users and ensure that the flooring products have the durability and longevity expected by the customers.

The acceptance standard specifications provide guidelines for the manufacturers to produce SPC flooring products that meet specific criteria related to wear resistance, slip resistance, formaldehyde and VOC emissions, fire resistance, and other important performance factors. Compliance with these standards helps to ensure that the SPC flooring products are safe, reliable, and of high quality.

Moreover, adherence to the acceptance standard specification can also benefit architects, interior designers, contractors, and end-users in selecting and specifying SPC flooring products. They can use the specifications to compare different products and make informed decisions based on the product’s quality, durability, and performance.

In summary, the SPC floor acceptance standard specification serves as a benchmark for quality and performance, and its purpose is to ensure that the SPC flooring products meet the expectations of the customers and perform well over their lifetime.

3. Requirements

A. Surface flatness, levelness, and acceptance criteria

The surface flatness refers to the evenness of the subfloor’s surface. The subfloor should be flat to within 3/16 inches in a 10-foot radius. This is equivalent to a variation of 0.3% or less. The flatness of the subfloor can be measured using a straightedge or laser level.

Surface levelness refers to the evenness of the subfloor in terms of its slope or inclination. The subfloor should be level to within 1/8 inch in a 6-foot radius. This is equivalent to a variation of 0.2% or less. The levelness of the subfloor can be measured using a leveling compound or self-leveling underlayment.

The acceptance criteria for SPC flooring in terms of surface flatness and levelness are typically defined by the flooring manufacturer or installer. Generally, the flooring industry accepts a maximum deviation of 1/8 inch in 10 feet for surface flatness and levelness. However, it is essential to consult the specific manufacturer’s installation instructions and recommendations to ensure that the acceptance criteria are met.

B. Defects, damage, and acceptance criteria

Surface defects can include scratches, scuffs, dents, and other visible surface imperfections. The acceptance criteria for surface defects typically depend on the size and number of defects per a given area of flooring.

Edge damage can occur during transportation or installation and may include chipping or cracking of the edges. The acceptance criteria for edge damage depend on the extent and location of the damage.

C. Acceptance criteria for visible surface irregularities

Visible surface irregularities, such as bumps or indentations, are not acceptable in the visible area of the flooring. These irregularities can affect the appearance and performance of the flooring.

4. Testing and Inspection

A. Testing procedure

The testing procedures for SPC (Stone Plastic Composite) flooring are designed to ensure that the product meets industry standards for quality, durability, and safety. Here are some common testing procedures for SPC flooring:

- Dimensional Stability Test: This test measures the change in size and shape of the flooring under different environmental conditions, such as changes in temperature and humidity.

- Tensile Strength Test: This test measures the force required to break or deform the flooring material. It helps determine the flooring’s durability and resistance to deformation.

- Impact Resistance Test: This test measures the flooring’s resistance to impacts and indentation from heavy objects or dropped items.

- Wear Resistance Test: This test measures the flooring’s ability to resist wear and tear, such as scratches and scuffs, over time.

- Slip Resistance Test: This test measures the flooring’s slip resistance to ensure that it meets safety standards and does not pose a slip or fall hazard.

- Chemical Resistance Test: This test measures the flooring’s resistance to various chemicals, such as acids, oils, and cleaning agents.

- Fire Resistance Test: This test measures the flooring’s ability to resist ignition and flame spread.

The specific testing procedures and standards for SPC flooring can vary depending on the manufacturer and the product’s intended use. It is essential to carefully review the manufacturer’s testing procedures and standards to ensure that the flooring product meets the necessary quality and safety standards.

B. Acceptance criteria

Here are some common acceptance criteria for testing and inspection of SPC flooring:

- Dimensional Stability: The change in size and shape of the flooring should not exceed a certain limit, as specified by the manufacturer or industry standards.

- Tensile Strength: The flooring should withstand a certain amount of force before breaking or deforming, as specified by the manufacturer or industry standards.

- Impact Resistance: The flooring should not show any visible signs of damage, such as cracking or indentation, after being subjected to a certain level of impact.

- Wear Resistance: The flooring should resist scratching and scuffing up to a certain level, as specified by the manufacturer or industry standards.

- Slip Resistance: The flooring should meet safety standards for slip resistance to prevent slip or fall hazards.

- Chemical Resistance: The flooring should withstand exposure to common household or industrial chemicals without showing any visible signs of damage or discoloration.

- Fire Resistance: The flooring should meet safety standards for fire resistance to prevent ignition and flame spread.

- Appearance: The flooring should meet the manufacturer’s standards for color, design, and overall appearance. The flooring should not have any visible defects, such as scratches, chips, or stains, that are outside the manufacturer’s acceptable limits.

5. Installation Requirements

A. Installation procedure

Here are the general steps involved in the installation procedure for SPC flooring:

- Acclimate the Flooring: Before installation, the SPC flooring should be stored in the installation area for at least 48 hours to allow it to acclimate to the temperature and humidity conditions of the room.

- Prepare the Subfloor: The subfloor should be clean, flat, and free of any debris or protrusions. If necessary, the subfloor may need to be leveled or repaired before installing the SPC flooring.

- Measure and Cut: Measure the length and width of the room and calculate how many planks or tiles will be needed to cover the floor. Cut the planks or tiles as needed using a saw or utility knife.

- Lay the First Row: Begin at the longest wall in the room and lay the first row of planks or tiles along the wall, leaving a 1/4-inch gap between the flooring and the wall to allow for expansion.

- Install the Rest of the Flooring: Continue installing the rest of the planks or tiles, making sure to stagger the joints for a more natural look. Use a tapping block and a hammer to lock the planks or tiles together.

- Install Trim and Molding: Install the trim and molding along the walls to cover the expansion gap and create a finished look.

B. Acceptance criteria

Here are some common acceptance criteria for SPC flooring installation:

- Expansion Gap: A 1/4 inch expansion gap should be left between the flooring and the walls, as well as any fixed objects such as pipes or cabinets, to allow for expansion.

- Adhesive: The adhesive used for installation should be suitable for SPC flooring and the specific installation method being used. The adhesive should be applied evenly and consistently.

- Joints: The joints between the planks or tiles should be staggered and tight-fitting, with no visible gaps or spaces.

- Floor Flatness and Levelness: The installed flooring should be flat and level, with no visible bumps or depressions. The flooring should not deviate from the subfloor by more than a certain amount, as specified by the manufacturer or industry standards.

6. Maintenance Requirements

A. Cleaning procedure

Here are the general steps involved in the cleaning procedure for SPC flooring:

- Sweep or Vacuum: Sweep or vacuum the floor regularly to remove dirt and debris that could scratch the surface of the flooring.

- Damp Mop: Damp mop the floor using a soft, microfiber mop or a well-wrung mop. Avoid using excessive water as it can seep into the joints and damage the subfloor.

- Use a Mild Cleaner: For tough stains, use a mild cleaner that is specifically formulated for SPC flooring. Avoid using abrasive or acidic cleaners, as they can damage the surface of the flooring.

- Rinse Thoroughly: After using a cleaner, rinse the floor thoroughly with clean water to remove any residue.

- Dry the Floor: Dry the floor thoroughly after cleaning using a clean, dry microfiber mop or a soft cloth.

B. Maintenance requirements

Here are some maintenance requirements for SPC flooring:

- Avoid Harsh Chemicals: Avoid using harsh chemicals, such as bleach or ammonia, on SPC flooring, as they can damage the surface of the flooring.

- Prevent Scratches: Prevent scratches on the surface of the flooring by using felt pads on the legs of furniture and avoid dragging heavy items across the floor.

- Regular Cleaning: Regular cleaning is essential to maintain the appearance and performance of SPC flooring. Sweep or vacuum the floor regularly to remove dirt and debris, and damp mop as needed using a mild cleaner that is specifically formulated for SPC flooring.

- Avoid Extreme Temperatures: Avoid exposing SPC flooring to extreme temperatures, such as those produced by radiant heating systems or direct sunlight, as it can cause the flooring to expand or contract.

- Maintain Relative Humidity: Maintain relative humidity levels between 30% and 60% to prevent excessive moisture from damaging the flooring.

- Inspect Regularly: Inspect the flooring regularly for any signs of damage, such as scratches or chips. Repair or replace damaged planks or tiles as needed.

- Professional Cleaning: Consider professional cleaning and maintenance services periodically to keep the flooring in optimal condition.

The SPC Flooring Acceptance Standards and Guidelines provide a comprehensive set of criteria to ensure that flooring products meet the highest quality standards. Following these standards and guidelines will ensure that the flooring is of the highest quality and will last for a long time.